i3D at the Glass Seminar 2025 of the The Finnish association of Flat Glass

How can glass companies improve their profitability?

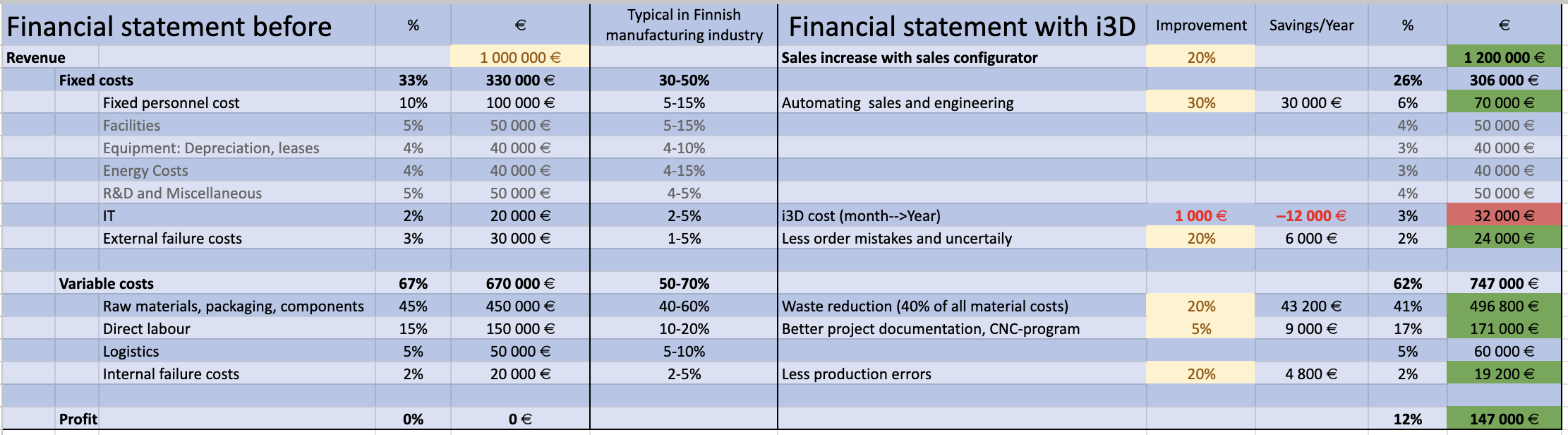

We approached the problem from a financial statement perspective and considered the impact of different options on company profitability. We created an example company to explore how automation, digitalisation and more efficient production management can reduce errors, speed up deliveries and optimise costs. The company has a turnover of €1M, but the business is not profitable and the operating margin is 0%. So something should be done…

A one of key challenges is the big share of fixed costs and scalability. The share of fixed costs increases as turnover increases (although in theory it should not) because processes are not scalable. The workload on the office side increases as sales increase.

Keeping fixed costs in check is the most direct route to better profitability. How can this be done in practice? The first step is to increase turnover through more efficient sales and planning, and this is where the configurator plays a key role.

From project production to mass production

Mass customisation enables a shift from project production to mass production. It combines an efficient quotation-order-delivery process with customisation to meet customer needs. This enables cost-effective manufacturing without compromising product customisation.

Glass companies need to choose their production strategy carefully.

- Engineer-To-Order (ETO) is suitable for unique glass structures where the design is made to order.

- Make-To-Order (MTO) works when products are customised and manufactured according to customer needs.

- Assembly-To-Order (ATO) works when products are customised according to the customer’s needs, but the components are ready-made.

- Make-To-Stock (MTS) can be the best option when products can be made to stock and fast delivery is required.

Of these, MTO and ATO are configurable, meaning that the designing is done before the order arrives. The product is built on the basis of pre-designed choices and rules in the configurator.

Turnover growth with the configurator

Configurator is a digital tool that allows customers and sales teams to customise products quickly and accurately. They simplify the sales process, shorten delivery times and reduce design errors.

How can Configurator help you increase your turnover?

- Customers and salespeople can design and order products directly without manual designing.

- Fast processing of quotes and orders shortens the sales cycle and enables higher order volumes.

- Integration with production systems reduces manual work and speeds up deliveries.

- Fewer design and production errors lead to more satisfied customers and repeat orders.

If your company’s current process requires several days to prepare a quote and send it to production, the configurator can automate this work in minutes. This allows you to serve more customers in the same amount of time and with better hit accuracy, resulting in increased revenue.

With sales working more efficiently, the focus can also be on making production more efficient, which is the next step in improving profitability.

In our example company, we introduced a configurator to help sales and in the first year alone, we were able to increase our €1M turnover by 20%. The operating margin was increased to 5% because fixed costs were kept constant through automation.

Speeding up sales and design work

Sales and planning efficiency has a direct impact on the competitiveness of the company. Quick and accurate quotes and smooth communication from sales to design and production speed up the entire supply chain.

- Automated 3D models, quotes and drawings reduce manual work and speed up the quoting process.

- Intelligent quotation calculation tools can accurately calculate material costs and manufacturing costs, improving the profitability of the quotation phase.

- Digital order processing ensures that information flows seamlessly from design to production without manual errors.

In the example company, the configurator helped to streamline sales and automate 90% of the planning phase after the order was placed. Savings amounted to €30 000 per year, bringing the operating margin to 7%.

Reduction of quality defects and waste

Errors and material waste can increase costs significantly. By optimising the flow of information and using a configurator, errors can be minimised and resource utilisation improved.

- Configurator-generated quotes and 3D models significantly improve the flow of information between customer and vendor, while significantly reducing order errors and thus quality costs.

- Clear production lists and documentation ensure that orders going into production are exactly right.

- Optimised sawing patterns reduce material waste and improve resource efficiency.

In the example company, improving quality and reducing material waste by 20% brought the operating margin close to 12% and brought more than €50 000 more direct profit.

Reducing manual design in the production process

Traditionally, glass production has involved manual design, but automation can significantly reduce this. This improves efficiency and reduces the risk of errors.

- Automated CNC program generation directly from the configurator minimises the need for manual programming.

- Clear production lists and visual work instructions speed up work steps and reduce human error.

- Automatically generated picking and cut lists make work more efficient.

In our example company, automated production documents resulted in additional annual savings of around €10 000 and a 12% increase in operating margin. After the first year, EBITDA was €147,000 in the plus side. The Configurator helped them to become a profitable company within a year – from zero to hero.

Figures for an example company before and after i3D implementation

Verification of the strength of glass structures

In the next year, an example company will start to develop automation in the area of strength calculation. The software can be used to automate the impact of wind, snow and water loads on the strength and safety of the structure. The calculated or tabulated values can be used to create a site-specific structure that meets regulatory requirements. The calculation can be used to ensure that structures meet all requirements at the tender stage.

Towards a more profitable and efficient future

In summary, glass companies don’t have to choose between efficiency and customer focus – intelligent automation enables both. Automation of office work and production processes is critical for glass companies to go from zero to hero – from zero profit to profitable growth.

Key lessons learned:

- A configurator accelerates sales and increases turnover.

- Automation and digitalisation can speed up production and significantly reduce errors.

- Optimising the order-supply chain reduces costs and improves profitability.